by David L. Ames

I retired from the University of Delaware and moved to Louisville, Kentucky, three years ago. The city has great late nineteenth-century historic architecture, the cost of living is reasonable, and I have family here.

The best thing about being retired is being able to do what you want. For me, it has meant spending more time on my own photography. Specifically, that is large format architectural photography, which I have been shooting for several years for the Historic American Buildings Survey (HABS), the Historic American Engineering Record (HAER), and the Historic American Landscapes Survey (HALS) of the National Park Service. These programs still require black-and-white, large format film photographs at 4”x5”, 5x7”, and 8”x10”. The archivally produced photos accompany drawings and histories and are transmitted to the Prints and Photographs Division of the Library of Congress, where they are available at the HABS/HAER/HALS Collection online. Although I can shoot 5”x7”, I prefer 4”x5” basically because it is faster and allows for more documentation.

The best thing about being retired is being able to do what you want. For me, it has meant spending more time on my own photography. Specifically, that is large format architectural photography, which I have been shooting for several years for the Historic American Buildings Survey (HABS), the Historic American Engineering Record (HAER), and the Historic American Landscapes Survey (HALS) of the National Park Service. These programs still require black-and-white, large format film photographs at 4”x5”, 5x7”, and 8”x10”. The archivally produced photos accompany drawings and histories and are transmitted to the Prints and Photographs Division of the Library of Congress, where they are available at the HABS/HAER/HALS Collection online. Although I can shoot 5”x7”, I prefer 4”x5” basically because it is faster and allows for more documentation.

One of my current projects is photographically documenting four of Kentucky’s surviving twelve covered bridges, which once numbered more than 700. I am doing these for Christopher Marston, project leader of the HAER National Covered Bridge Recording Project. Although I had documented one covered bridge earlier in Maryland, I wanted to know more about the engineering and characteristics of covered bridges so I would be sure to capture their character-defining features. Because there is a large amount of literature on covered bridges, I was able to give myself a crash course on them before heading out into the field.

In researching a historic resource that’s new to me, I like to begin by developing an historic context to understand how it evolved and what its principal characteristics are. The first thing I learned was that technologically, the covered bridge is the opposite of its popular romantic, nostalgic image of a quaint, obsolete, relic of the past as reflected in such novels as The Bridges of Madison County. A recent book published by HAER, Covered Bridges and the Birth of American Engineering (2015), makes the case that the development of wooden truss bridges was significant in the early development of American civil engineering.1 Since it was plentiful and a strong, durable, natural resource, wood was the ideal material for experimenting with bridge trusses.

Evolution of American Truss Bridges

American wooden truss bridges evolved in two broad periods—1790 to ca. 1840 and ca. 1840 to 1900. The historic era of American covered bridge building continued into the mid-twentieth century.2

The major factor driving early American bridge development was the need to carry heavier loads over longer distances in a rapidly expanding young republic, with less expensive, lighter, but stronger and longer bridges. Thus, the timber bridge evolved from a labor-intensive, hand-crafted, expensive structure to an engineered one assembled from manufactured components requiring lower skilled labor at less cost.

In the nascent period of timber bridge evolution from 1790 to 1840, bridge builders would draw upon the ancient triangular-shaped truss types: kingpost, queenpost, and multiple kingpost, to create a number of empirically-tested, innovative wooden truss bridges.

Dating from medieval times, the kingpost truss is a triangular frame with a single center post—the kingpost—flanked by diagonal braces carrying the load to the end of the bottom chord, which in turn rest on abutments at either end. A queenpost is like a two half kingposts with a horizontal cross member or top chord in between, to allow the base of the bridge to be longer and to span wider streams. The multiple kingpost is a series of kingposts or posts with braces, to span even longer distances.3

The first long-span wooden truss bridge is thought to be a bridge across the Connecticut River between Walpole, New Hampshire, and Bellows Falls, Vermont, completed in 1785. The first documented covered bridge in the United States was the 1804 Schuylkill Permanent Bridge in Philadelphia. Supported by stone arches and carrying the King’s Highway, the 3-span, 600-foot, arched wooden bridge was seen as an engineering masterpiece. Costing an extraordinary $300,000, it was covered to protect the structural timber trusses from the weather.4

Although there was a great deal of experimentation in the early empirical period of truss development, the two most significant American trusses developed were the arched truss and the lattice truss. Although other builders developed arched trusses, the most widely used was by Theodore Burr, who patented his design in 1806. His arch-truss consisted of a segmental arch sandwiched between two multiple kingpost trusses. With his truss, he set a then-record for a single span of 360 feet and four inches over the Susquehanna River at McCall’s Ferry, Pennsylvania.5 Of the thousands of Burr arch-truss bridges built, about 185 examples have survived. In Kentucky, Lewis Wernwag, another prolific builder of arched covered bridges, constructed several arch-truss bridges for the Maysville-Lexington Turnpike Company in the 1830s.

Although there was a great deal of experimentation in the early empirical period of truss development, the two most significant American trusses developed were the arched truss and the lattice truss. Although other builders developed arched trusses, the most widely used was by Theodore Burr, who patented his design in 1806. His arch-truss consisted of a segmental arch sandwiched between two multiple kingpost trusses. With his truss, he set a then-record for a single span of 360 feet and four inches over the Susquehanna River at McCall’s Ferry, Pennsylvania.5 Of the thousands of Burr arch-truss bridges built, about 185 examples have survived. In Kentucky, Lewis Wernwag, another prolific builder of arched covered bridges, constructed several arch-truss bridges for the Maysville-Lexington Turnpike Company in the 1830s.

Because arched trusses were labor-intensive, expensive, and time consuming to build, “builders began looking for ways to simplify construction so that substantial bridges could be built quickly and affordably in more locations.”6 The answer came in the form of the lattice truss bridge invented in 1821 by the influential American architect Ithiel Town. Relatively cheap, strong, and easy to build in spans up to 200 feet, the “Town truss design consisted of a lattice of overlapping planks fastened together with treenails (wood pins).”7 Several early railroad bridges used the Town lattice truss, and it would continue to be used for highways well into the twentieth century.8

The rapid growth of railroads in the 1830-40s fueled a demand for bridges that could be rapidly constructed. This in turn stimulated greater research to understand the dynamics of trusses and how the elements of a bridge functioned under loading.

The first bridge builder to apply mathematics to the design of trusses was West Point–trained Major Stephen H. Long, who patented his Long truss in 1830. It was a “traditionally framed truss with paired diagonal braces and single counter braces crossing within each panel.”9 Its engineering significance was that it created permanent stresses within a structure to improve its performance under loading.10

The next major step in the development of the engineered covered bridge was the introduction of metal by substituting wrought iron ties for wood posts and braces. With the seemingly simple improvement of substituting an iron tie bar for vertical wooden post, in 1840 William Howe brought about what has been called a revolution in bridge building. Using adjustable, wrought iron vertical tension rods and cast iron angle blocks, connecting between diagonal timber braces and counter braces, the Howe truss was a major transitional structure in the development of the all metal truss.11 The Howe truss also lowered the cost of bridge construction because panels could be prefabricated and shipped to construction sites. Very popular on mid-nineteenth century railroads across the country, former Chief of HAER and bridge historian Eric DeLony claimed that “the Howe truss may be the closest wooden-bridge design that ever came to perfection.”12

The last two most significant wood trusses developed in the nineteenth century were the Pratt truss of 1844 and Smith trusses of 1867. Patented in 1844, the truss designed by Thomas W. Pratt was a variation on the Howe Truss. It was a combination panel truss that reversed the use of iron tie rods of the Howe truss, using the tie rod for the diagonal braces rather than vertical posts.13 Ironically, the Pratt truss was originally developed as a composite wood and iron truss that would evolve into the most widely used all-iron and later all-steel Pratt truss.

Robert W. Smith’s 1867 wood truss designs combined strength with lightness. “They had light elongated Xs with no verticals and no iron except [for] a few bolts.”14 His light truss has been called a “titanium” breakthrough in truss design. Smith’s factory production allowed him to build several thousand bridges by prefabricating all of their components in his factory and shipping them to construction sites. Smith’s major contribution was to perfect standardization and industrialization of bridge construction.15

Kentucky’s Covered Bridges16

It is unknown how many covered bridges were in Kentucky at their peak. There may have been more than 700 at one time, but that number had dropped to 400 by 1900. Unfortunately, Kentucky started its efforts to evaluate and preserve covered bridges much later than neighboring Ohio (150 extant) and Indiana (94 extant), so today only 12 survive; many of which have been recently rehabilitated.17

Kentucky’s extant covered bridges were built with a variety of truss types: kingpost, queenpost, combination king- and queenpost, Burr-arch, Town lattice, Smith-variant, and a Wheeler truss.

HABS/HAER/HALS Documentation of Kentucky’s Covered Bridges

Two of Kentucky’s covered bridges were documented by HABS in the 1930s, as part of a state survey of historic buildings. The “Wood-Covered Bridge” over the Licking River at Butler, Pendleton County (HABS KY-20-11), was a three-span Burr-arch truss built in 1870 and recorded prior to its demolition. The roof and siding had already been removed when Theodore Webb photographed the 460’-long bridge in February 1934, a rare opportunity to reveal the timber truss. Webb and company recorded another Burr-arch over the South Branch of the Licking River at Cynthiana, Harrison County the same year (HABS KY-20-20).

The Federal Highway Administration (FHWA) began administering the National Historic Covered Bridge Preservation (NHCBP) Program in 1998, a program that would go on to provide funds to rehabilitate nearly 250 bridges. With support from the NHCBP for research and education, HAER started a multi-year initiative: the HAER National Covered Bridge Recording Project. Led by project manager Christopher H. Marston, HAER would record nearly 100 covered bridges, designate seven as National Historic Landmarks, hold two national conferences, and publish two books. In addition to Covered Bridges and the Birth of American Engineering in 2015, Marston and Thomas Vitanza co-edited the Guidelines for Rehabilitating Historic Covered Bridges in 2019.18

HAER studied two Kentucky bridges as part of the NHCBP. In 2003, Lola Bennett recorded the ca. 1874 Bennett’s Mill Bridge over Tygart’s Creek in Greenup County, which represented the last surviving example of the regional Wheeler truss in the country. The bridge was reconstructed in 2003. For the Guidelines, Marston and Vitanza included a case study on the rehabilitation of the Johnson Creek Covered Bridge, which was completed by Arnold Graton in 2009. In addition, the NHCBP provided funding to rehabilitate at least five Kentucky bridges.

In 2018, I told Christopher Marston I was interested in documenting some Kentucky covered bridges to HAER photographic standards. He selected the bridges after consulting with Bill Caswell, President of the National Society for the Preservation of Covered Bridges, which recently had a tour of Kentucky.19 We agreed on the following four bridges:

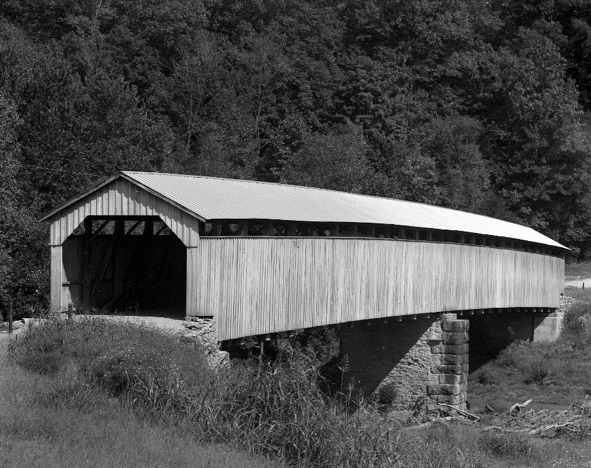

- Beech Fork Bridge (HAER KY-54) ca. 1865 — 2 spans totaling 211 feet, longest extant covered bridge in state. Burr-arch truss; rehabilitated 2016-17.

- Johnson Creek Bridge (HAER KY-55) 1874 — 110 feet, variant of Smith truss; arch added early 1900s; rehabilitated 2007-09.

- Cabin Creek Bridge (HAER KY-56) ca. 1867-1875 — 114 feet, multiple kingpost truss with arches; rehabilitated 2013.

- Goddard Bridge (HAER KY-57) Unknown date, possibly 1864 — 63 feet, Town lattice truss; moved 1932; rehabilitated 2004-06.

The first step for photographing bridges is finding them, which seemed like a simple task. While several maps are available online, actually getting to them presented some difficulties. First, their remoteness in valleys or hollows may partly explain why they survived. Second, Kentucky has a warren of back roads that are not always marked by signs or do not even appear on maps. Being a geographer, I still believe in paper maps, and I secured a large atlas of Kentucky plus a statewide road map. Although the atlas was my primary source, it was the GPS on my iPhone that actually and amazingly wove me to the bridges on some roads that weren’t even on the maps. The trick was to find origins and destinations in the atlas that the iPhone recognized close to the bridges. In some cases, the iPhone got me close and the atlas finally got me there. Successfully finding them was a collaboration between paper maps and digital GPS.

The photography requirements of HABS/HAER/HALS have two elements. The most well-known one is that HABS/HAER/HALS requires the use a large-format camera (4x5, 5x7, or 8x10) for most documentation, and the second is a protocol for shooting a structure that provides comprehensive systematic coverage. Documentary photography creates a visual data collection for analysis by architectural and engineering historians and historic preservationists. Its purpose is to collect as much information in as few photographs as possible, and the rationale for the large format camera is that details can be enlarged from the large negative. But HABS and HAER photography have different priorities related to the different missions of the programs. HABS concentrates on documenting structure, while HAER concentrates more on documenting the process that takes place in a structure, if applicable.

Getting the most information in the fewest photographs also relates to the time required to photograph with a large format camera. Ten to fifteen exterior photographs a day is typical, while fewer can be done on interiors especially if lighting is required. Other than single photographs of the front and one side of the structure for a survey, HABS suggests that the minimum coverage of a building consists of four exterior photographs: perspectives of the front and one side; the rear and the other side; an elevation of the front—straight-on view; and an environmental view of the structure as part of the larger landscape. Additional photos would consist of major architectural elements and then details. My preferred sequence would be to move around the building counterclockwise. For interiors, the sequence would be from major to minor rooms by floor.

For determining the sequence of photographs for covered bridges, I followed the master list of features of covered bridges found in Appendix C of Guidelines for Rehabilitating Covered Bridges. There are four categories: superstructure features including the truss and its connections, floor structure, and lateral bracing; substructure features supporting the bridge, including abutments, piers, and wing walls; the exterior envelope, including siding, portal, roof, and wall openings; and finally, the environmental context of approach, site, and setting features. Below, I have established a list of ten basic views for all covered bridges.

EXTERIOR ENVELOPE

- Environmental shot, or what I call a “crossing” shot, which shows the entire bridge—perspective of portal and one side

- Perspective of opposite portal and the other side of the bridge

- Elevation of one portal

- Abutments—on either end of covered bridges; they are often different because of different shore conditions and repairs

SUPERSTRUCTURE FEATURES

- “Barrel shot” of trusses—a wide angle view down the middle showing trusses on both sides

- Perspective of entire truss on one side

- Elevation of a typical truss panel

- Floor/deck surface

- Supporting floor structure from underneath

- Details of truss joinery, connections such as tie bars, bracing, etc.

The four minimum essential views in order of importance are:

- “Barrel shot” of trusses—a wide angle view down the middle showing trusses on both side

- Perspective of entire truss on one side

- Elevation of typical truss panel

- Perspective of portal and one side

Before going into the field, I use secondary photographic sources to develop a “shoot list” based on my protocol, and type it up. Upon arrival at the site, I inspect the bridge and modify the shoot list based on the specifics of the bridge. I also shoot the list with a digital camera to test the perspectives to have photos to help ID the large format negatives later, as when shooting more than one bridge on a trip it is hard to tell the difference later between trusses. While shooting I use the shoot list to make notes on lens used and exposure. Having learned from experience, I now shoot the four minimum views first to be sure I have them and then complete the others.

Before going into the field, I use secondary photographic sources to develop a “shoot list” based on my protocol, and type it up. Upon arrival at the site, I inspect the bridge and modify the shoot list based on the specifics of the bridge. I also shoot the list with a digital camera to test the perspectives to have photos to help ID the large format negatives later, as when shooting more than one bridge on a trip it is hard to tell the difference later between trusses. While shooting I use the shoot list to make notes on lens used and exposure. Having learned from experience, I now shoot the four minimum views first to be sure I have them and then complete the others.

This project has been more time-consuming to complete them than I thought it would be. I’ve been at it about a year. Getting to my last bridge—Goddard—is a good example of a fieldwork adventure. I had completed three bridges by early June and only had Goddard Bridge left before it started raining . . . and raining. I had my cameras packed and by the door, ready to head out on the first sunny day. That came on a sunny Sunday so off I went to find the Goddard Bridge—about a two-hour drive from Louisville. But with the sun came the heat in excess of 90 degrees. When I got there, I discovered that it was still an operating bridge, with its single lane busy with morning traffic. The three other bridges were preserved landmarks closed to traffic. Never assume anything! I couldn’t shoot the trusses from inside without stopping traffic. I took some basic exteriors but after about an hour in the 90-degree heat, and carrying the big 4x5 camera and tripod around, I was beginning to fade. I decided to call it a day and check out a couple of other bridges in the area. Fleming County has the most covered bridges in the state and is home to the Fleming County Covered Bridge Museum. I would have to come back to get the interiors.

I returned the following Sunday morning with the temperature “only” in the 80s—just in time to find parishioners crossing the bridge for church! (There is a little white church on the other side of the bridge.) Actually, everything worked out. While they went to church, I took my photos; they left after church while I took a break. After I finished the interiors I headed home, having finally completed the field work on this project.

After I’m done processing these large format photographs and submit them to HAER for transmittal to the Library of Congress, I plan to go on to document the other covered bridges in the state of Kentucky.

--David L. Ames is Professor Emeritus of Urban Affairs and Public Policy, University of Delaware

1. Justine Christianson and Christopher H. Marston, executive editors, Covered Bridges and the Birth of American Engineering (Washington, DC: Historic American Engineering Record, National Park Service, 2015).

2. Lola Bennett, “History of Covered Bridges in the United States, in Covered Bridges and the Birth of American Engineering, ed. Christianson and Marston (Washington, DC: Historic American Engineering Record, National Park Service, 2015), 68.

3. Robert A. Powell, Kentucky’s Covered Bridges & Water Kills (Danville, KY: Silverhawke Press, Rev 2017), 61.

4. Bennett in Christianson and Marston, 51-53.

5. Powell, 65.

6. Bennett, in Christianson and Marston, 57.

7. Bennett, in Christianson and Marston, 57.

8. Terry Miller and Ronald G. Knapp, America’s Covered Bridges: Practical Crossings – Nostalgic Icons, (Rutland, VT, Tuttle Publishing, 2013), 68-69.

9. Bennett, in Christianson and Marston, 59.

10. Bennett, in Christianson and Marston,59.

11. Powell, 66.

12. Eric DeLony, “The Golden Age of the Iron Bridge,” Invention & Technology 10, no. 2 (Fall 1994), 11.

13. Bennett, in Christianson and Marston, 61.

14. Joseph D. Conwill, Covered Bridges Across North America (St. Paul: MBI Publishing Company, 2004), 27.

15. Miller and Knapp, 76-77.

16. Much of my material on Kentucky’s wooden covered bridges is from Robert A. Powell, Kentucky’s Covered Bridges & Water Mills, (Danville: Silver Hawke Publications, 1985, rev. 2017) and Robert W. M. Laughlin and Melissa C. Jurgensen, Images of America: Kentucky’s Covered Bridges (Charleston: Arcadia Publishing, 2007). Another good source is Miriam F. Wood and David A. Simmons, Covered Bridges: Ohio, Kentucky, West Virginia (Wooster, Ohio: Wooster Book Co., 2007).

17. “Kentucky’s Covered Bridges,” Society for Industrial Archeology Newsletter 8, nos. 1 & 2, January & March 1979, 10. David Wright, ed. World Guide to Covered Bridges. 7th ed. National Society for the Preservation of Covered Bridges, 2009.

18. Christopher H. Marston and Thomas A. Vitanza, Guidelines for Rehabilitating Covered Bridges (Washington, DC: Historic American Engineering Record, 2019).

19. Bill Caswell also started the useful web site that attempts to inventory every known covered bridge in North America: Covered Spans of Yesteryear, http://www.lostbridges.org/